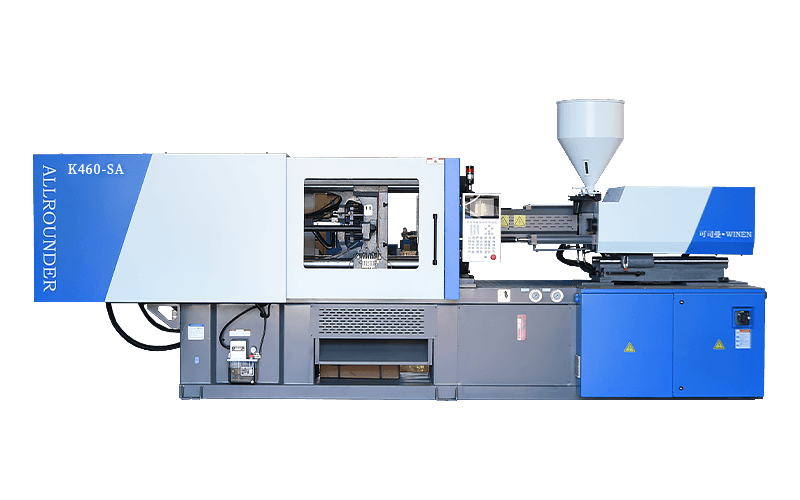

What is a Fruit Basket Plastic Injection Molding Machine?

A fruit basket plastic injection molding machine is a specialized machine used in the manufacturing process of plastic fruit baskets. It utilizes the principles of injection molding, an automated process where molten plastic is injected into a mold cavity, which then solidifies into the desired shape of the fruit basket. This machine ensures precision, efficiency, and consistency in producing high-quality plastic fruit baskets.

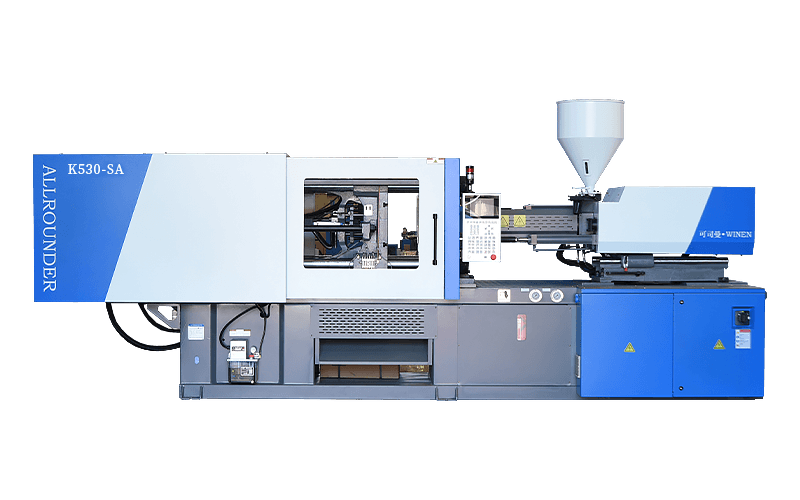

Fast and Efficient Production:

The fruit basket plastic injection molding machine is known for its high-speed production capabilities. It can produce a large number of fruit baskets in a short amount of time due to its automated and continuous operation. This fast production rate is particularly advantageous in meeting high-demand scenarios, such as during peak fruit seasons or large-scale fruit exports.

Durability and Sturdiness:

Fruit baskets need to be strong and durable to withstand the weight and pressure of various fruits. The plastic injection molding process allows for the production of solid and sturdy fruit baskets, capable of safely containing and transporting fruits without the risk of breakage or damage. The uniformity of the molded baskets ensures consistency in strength and performance.

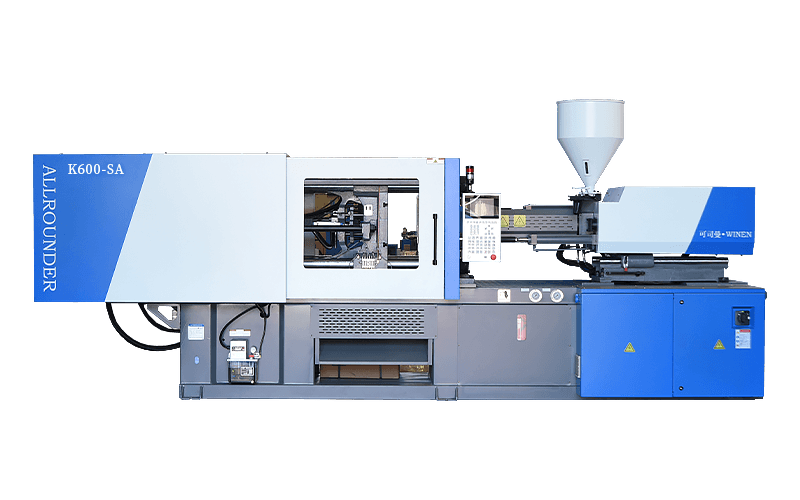

Customization and Design Flexibility:

The fruit basket plastic injection molding machine offers a high degree of customization and design flexibility. With the ability to control various parameters during the molding process, manufacturers can produce fruit baskets of different sizes, shapes, colors, and textures. This flexibility allows for the creation of unique and visually appealing fruit baskets, providing market differentiation and consumer appeal.

Cost-Effectiveness:

The cost-effectiveness of the fruit basket plastic injection molding machine contributes to its popularity in the packaging industry. The automated operation of the machine requires minimal labor, reducing production costs. Additionally, the high-volume production capability and low waste production optimize material usage, further minimizing expenses. The durability of the plastic fruit baskets also adds to the cost-effectiveness, as they have a long lifespan, avoiding the need for frequent replacements.

Environmental Considerations:

Plastic injection molding offers certain environmental benefits compared to other packaging materials. Plastic fruit baskets can be recycled and reused, reducing the amount of waste that ends up in landfills. Additionally, the durability and reusability of the baskets promote sustainability by minimizing the need for single-use packaging. Manufacturers utilizing the fruit basket plastic injection molding machine can contribute to a more circular and eco-friendly packaging system.

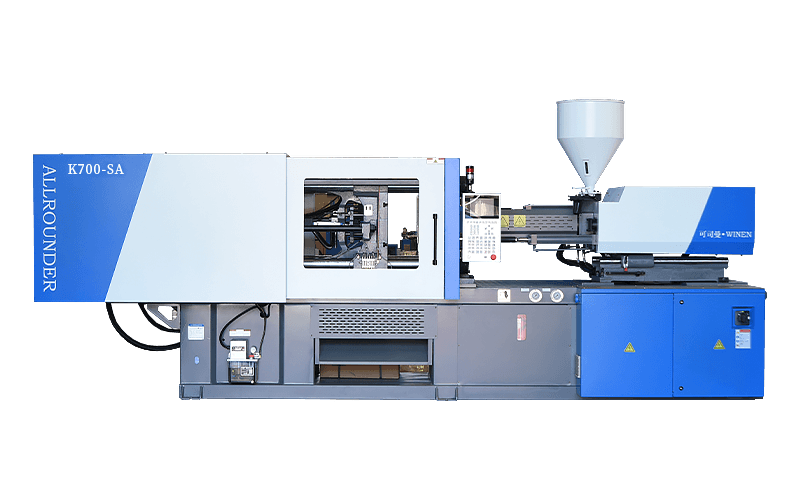

Applications:

The fruit basket plastic injection molding machine is not limited to producing fruit baskets alone. Its versatility allows for the production of various other plastic products used in the packaging industry. These products include food containers, storage boxes, crates, and other forms of transportation and storage solutions. The machine's capability to produce high-quality plastic products offers a wide range of packaging options for different industries.

English

English 中文简体

中文简体