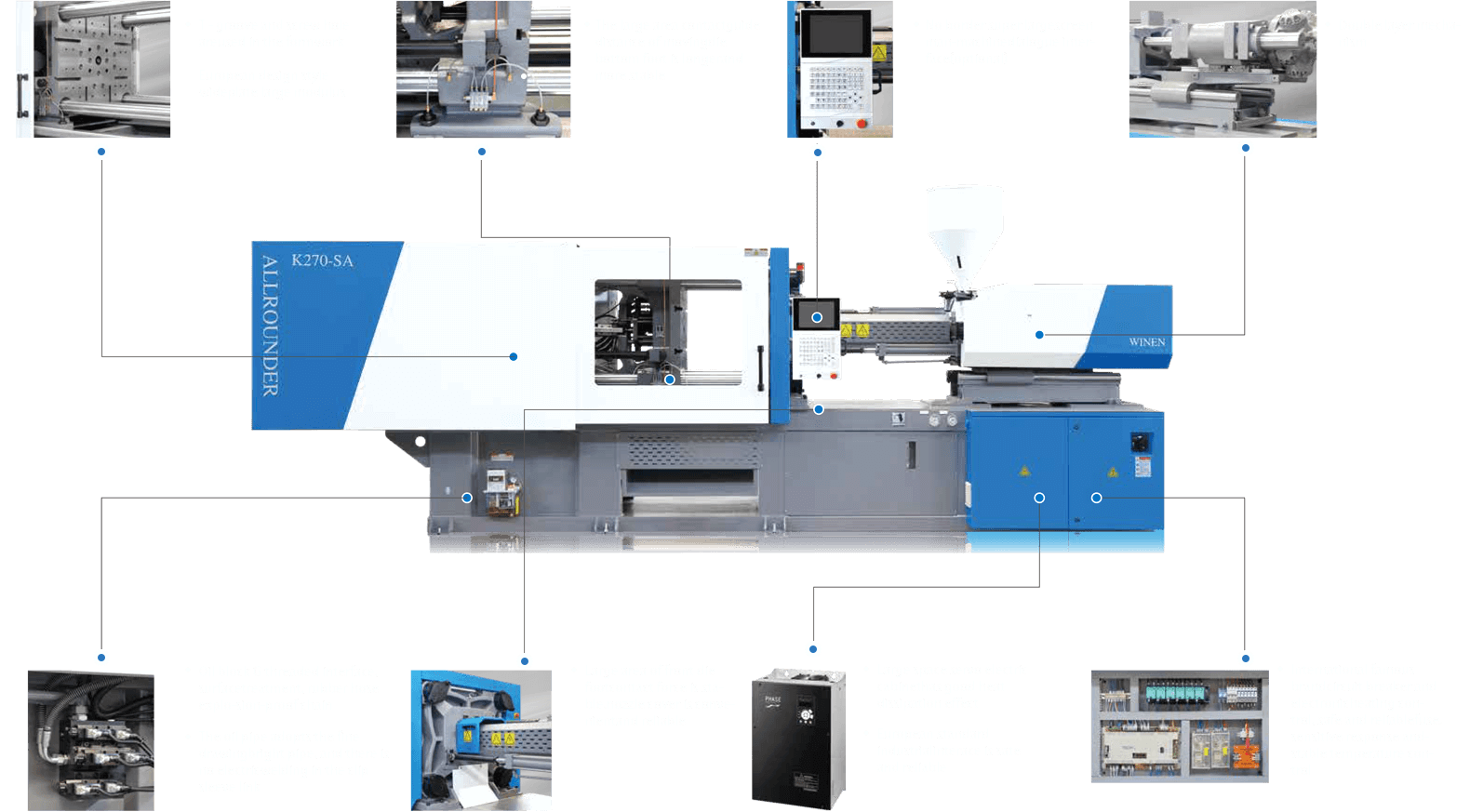

High Precision Injection Molding Machine

|

DESCRIPTION |

UNIT |

K270-SA

|

|||

|

INTERNATIONAL SIZE RATING |

1400 |

||||

|

|

A |

B |

C |

||

|

INJECTION UNIT |

Screw diameter |

mm |

55 |

60 |

65 |

|

Screw L:D ratio |

|

21.8 |

20.0 |

18.5 |

|

|

Shot volume |

cm3 |

713 |

848 |

995 |

|

|

Shot weight(PS) |

g |

649 |

772 |

906 |

|

|

oz |

22.9 |

27.2 |

32.0 |

||

|

Injection pressure |

Bar |

2114 |

1777 |

1514 |

|

|

Injection rate |

cm3/s |

243 |

288 |

338 |

|

|

Plasticizing capacity |

g/s |

36 |

46 |

56 |

|

|

Max.screw speed |

r/min |

220 |

|||

|

CLAMPING UNIT |

Clamping force |

kN |

2700 |

||

|

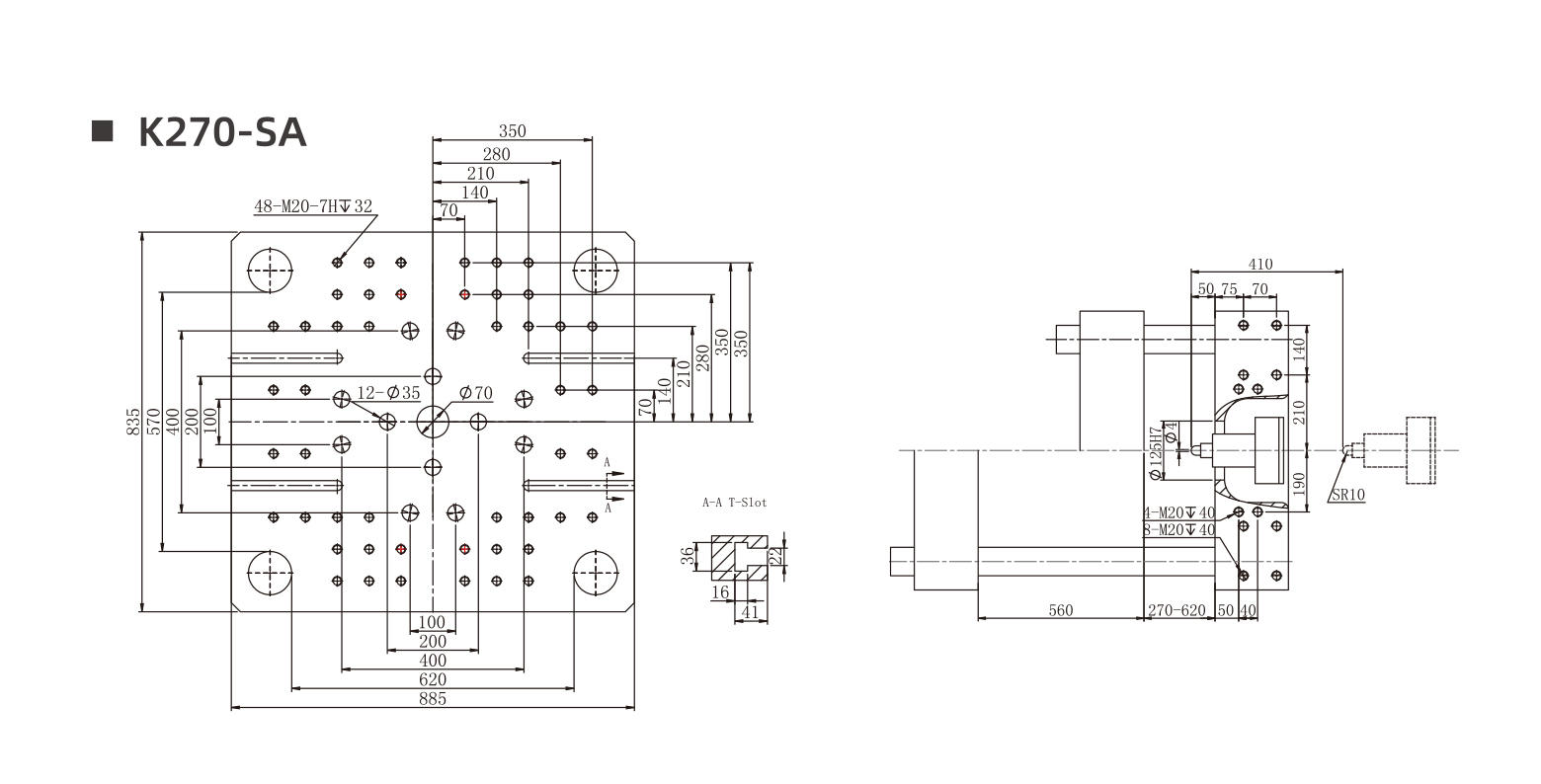

Space between tie bars |

mm |

620x570 |

|||

|

Platens size |

mm |

885x835 |

|||

|

Opening stroke |

mm |

560 |

|||

|

Min.mold height |

mm |

270 |

|||

|

Max.mold height |

mm |

620 |

|||

|

Distance between platens(daylight) |

mm |

1180 |

|||

|

Ejector stroke |

mm |

150 |

|||

|

Ejector force |

kN |

80 |

|||

|

Number of ejector |

|

13 |

|||

|

POWER UNIT |

Systerm pressure |

Bar |

175 |

||

|

Pump motor |

kW |

30 |

|||

|

Heating capacity |

kW |

16.0 |

|||

|

GENERAL |

Oil tank capacity |

L |

300 |

||

|

Machine dimension(LxWxH) |

m*m*m |

6.0x15x2.3 |

|||

|

Machine weight |

t |

9.0 |

|||

|

Hopper capacity |

kg |

50 |

|||

|

No |

Component configuration |

Brand |

Place of origin |

Configuration scope |

|

1 |

controller |

Taiwan Techmation(AK628)8-inch aluminum milling |

Taiwan |

K110-230 |

|

2 |

controller |

Taiwan Techmation(TECH1)8-inch aluminum milling |

Taiwan |

K270-460 |

|

3 |

controller |

Taiwan Techmation(TECH2)12 inch aluminum milling |

Taiwan |

K530-800 |

|

4 |

Servo oil pump |

USA HIGH-TECH |

U.S.A |

Full range |

|

5 |

servo motor |

PHASE |

Italy |

Full range |

|

6 |

servo drive |

PHASE |

Italy |

Full range |

|

7 |

Servo kit |

Germany Rexroth |

Germany |

Optional |

|

8 |

Reversing valve |

Japan YUKEN |

Taiwan |

Full range |

|

9 |

Reversing valve |

USA VICKERS |

U.S.A |

Optional |

|

10 |

Pre plastic motor |

DANDUN |

China |

Full range |

|

11 |

Mold adjusting motor |

DANDUN |

China |

Full range |

|

12 |

Sealing element |

U.KHALLITE |

britain |

Full range |

|

13 |

lubrication system |

HERG |

China |

Full range |

|

14 |

Circuit breaker |

SCHNEIDER ELECTRIC |

France |

Full range |

|

15 |

air switch |

SCHNEIDER ELECTRIC |

France |

Full range |

|

16 |

Electronic ruler |

Bonny |

U.S.A |

Full range |

|

17 |

Electronic ruler |

NOVOtek |

Germany |

Optional |

|

18 |

Solid state relay |

FOTEK |

Taiwan |

Full range |

|

19 |

Travel switch |

SCHNEIDER ELECTRIC |

France |

Full range |

|

20 |

Proximity switch |

FOTEK |

Taiwan |

Full range |

|

21 |

Screw barrel |

TONGDA |

China |

Full range |

High standard factory

Ningbo KSM Machinery Manufacturing Co.,Ltd. is a cooperate with Italy technologies specialized high-grade plastic in production of high-grade plastic molding machine. Our corporation is located in Ningbo Beilun Xing Ao Industrial Park. We have a number of R&D personnel and cooperate with a group of high-tech enterprise. As a professional China K270-SA-High Precision Injection Molding Machine suppliers and OEM/ODM K270-SA-High Precision Injection Molding Machine company, It mainly produces high precision injection molding machines with the clamping force range from 110T to 1850T. The products have high rigidity structure and equipped imported hydraulic & electrical elements, used screw with mixing head in order to have excellent plastifying performance and be suitable for various engineering plastic injection molding and the uers'special order are available. Since its corperation established, has always paid attention to enterprise reputation,carrid out scientific, management with rational designs, rests with quality pre-sale, selling and after-sale services to win the vast number user's trust and approval. We abide by the motto of "honest, keep on improving, lay stress on quality, never relax in effort". Sincerely welcome friends from all wask for guidance. The company has a research and development center with strong development strength. At the same time, it cooperates with domestic universities and colleges to develop and research injection and plastic production equipment and injection molding machine. The company has advanced hose testing equipment and experimental equipment. In recent years, the R&D center has achieved many achievements in injection molding machine and plastic equipment, rubber vulcanization process and formulation development. Sincerely invite customers at home and abroad to visit our factory, and look forward to your long-term corporation to create a beautiful tomorrow for you!

Why choose us

We have our own testing lab and advanced and complete inspection equipment, which can ensure the quality of the products produced by our equipment.

Our annual production capacity is over 500 set injection molding machine.

We focus on developing high-quality products for top-endmarkets. Our products are in linewith international standards, and are mainly exported to Europe, America,Japan and other destinations around the world.

We are only 15 kilometers away from the Ningbo Port, it is very convenient and efficient to ship goods to any other countries.

Guarantee High Quality With Our Expertise

Authentic reliable quality naturally stands out and fears no comparison.

Provide you with the latest enterprise and industry news

1. Basic concept of multi-cavity moldsMulti-cavity molds refer to the setting of multiple cavities o...

Importance of cooling cycle in Plastic Injection Molding MachineThe cooling cycle refers to the time...

1. Energy efficiency performance of PET injection molding machinesPET injection molding machines are...

1. High-efficiency oil-electric hybrid systemThe Oil-electric High Speed Injection Machine uses an...

Application of oil cooling system in plastic injection molding machineAs an efficient cooling method...

As a key equipment in modern industrial production, the automation of PET injection molding machines...